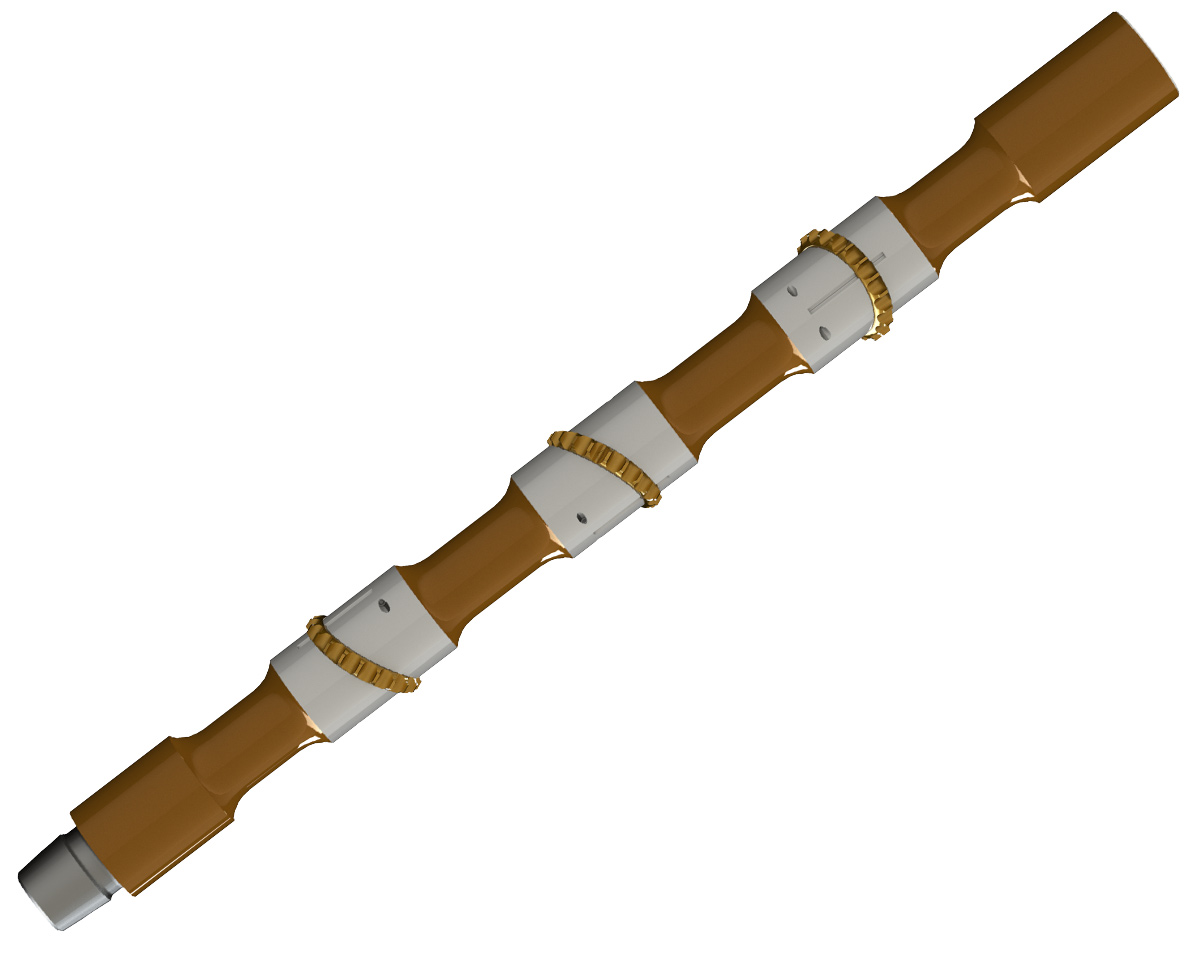

The Helix

The Helix is a stabilized roller reamer designed to improve the wellbore profile by reaming the doglegs and microledges that hinder the completion of a well when running liner or casing to bottom. Designed to reduce friction and drive weight to bit, the patented helical profile of the cutting rings stabilize the drill string while driving the tool downhole.

Overview

Three offset cutting rings rotate around the mandrel on carbide running surfaces. The angle of these rings generate six points of contact, evenly distributed in a helical configuration, providing 360 degree wall contact and bringing the hole to gauge. Tilted cutting rings provide flow passage for cutting returns. Localized friction is reduced and a “tractor” effect is generated by isolating the drill string from the wellbore through the free spinning cutting rings.

Technical Specifications

| Tool Size (OD) | 5.00″(127 mm) |

|---|---|

| Tool ID | 2.25″(57.1 mm) |

| Available Cutter Head Size (Cutting OD) | 5.875″(149.2 mm) to 6.75″ (171.5mm) |

| Overall Length | 63″(1.60 m) |

| Total Weight | 225 lbs. (102 kg) |

| Recommended Flow Range | 150-350 gpm (0.57-1.325 m3/min) |

| Temperature Range | N/A |

| Recommended RPM | 0-120 rpm |

| Operational Pressure Drop Generated | 5-10 psi (35-70 kPa) |

| Max Pull | 320,000 lbs. (1,356 kN) |

| Torsional Load To Yield Body Connection | 20,000 ft.lbs (27,050 Nm) |

| Connections (*Other Connections Available Upon Request) | 3 1/2 IF & 4 FH DS40 Pin & Box |